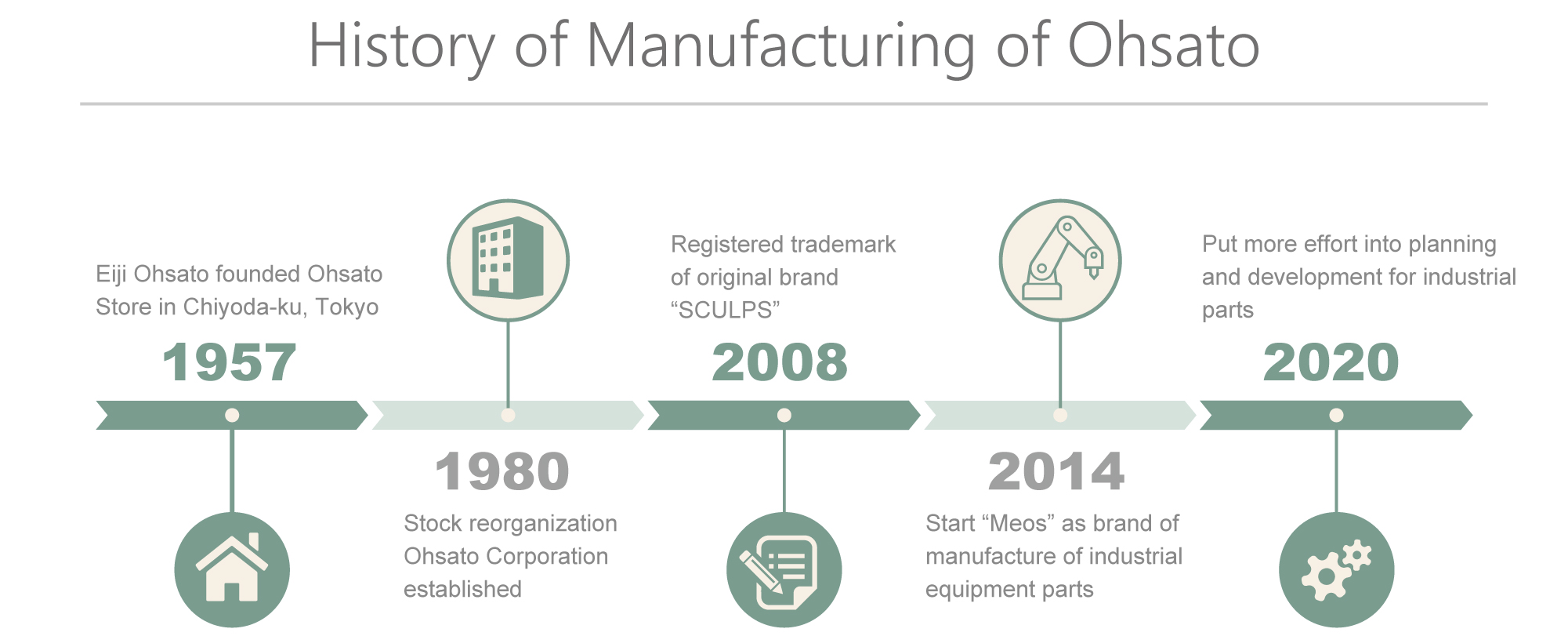

We propose optimal manufacturing process and mass production for each product.

Development of industrial equipment parts

Meos

Manufacturing that connects thoughts

We strive to meet each customer’s unique desires through manufacturing, whether it’s a product with specific standards or solving particular problems. Our commitment extends beyond product development to include offering added value through more efficient manufacturing methods and cost reduction. With creative thinking and problem-solving that go beyond mere ‘connecting parts,’ we shape your ideas into reality.

- Planning

- Development

- Connecting parts

- Various metal processing

- Resin formation

- Manufacturing process and mass-producing metal parts

Ohsato provides answers to customer issues and concerns

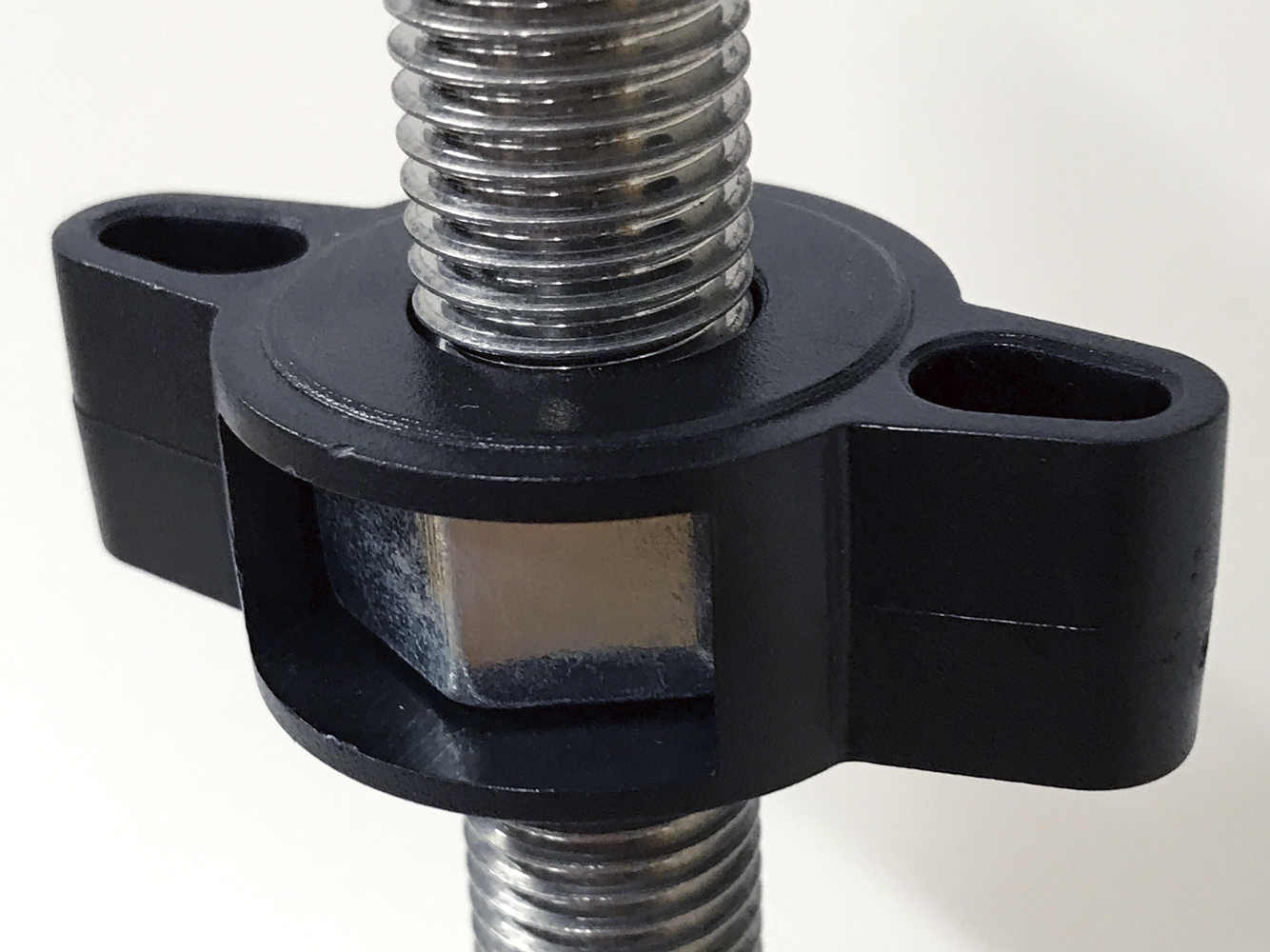

Case1:Examples of solutions for fastening parts

Requests from customers

Usually, we are using the button washers to connect each panel, but sometimes these come off when we use them. Though it does not happen so often, we are concerned about the fee that we pay for these to fix every time. So we want to solve this problem.

Solution of Ohsato

・Achieving 800N extraction force.

・Reduction of parts falling by a load of resistance.

・Cost reduction of summarizing the parts which will be able to cut(6to3).

・Cost reduction of about 600000 yen per year by recusing non-conforming products.

Verification

・Falling off the parts are "0" after changing.

・High evaluation and customer complaints are "0" after changing.

・No customer complaint so no payment of repair will cost.

Screws are used in most products and buildings. Although inconspicuous, reviewing these screws has a great impact on the quality and cost of products. Ohsato supports customers to improve quality and reduce costs with our rich know-how and technology for fastening parts.

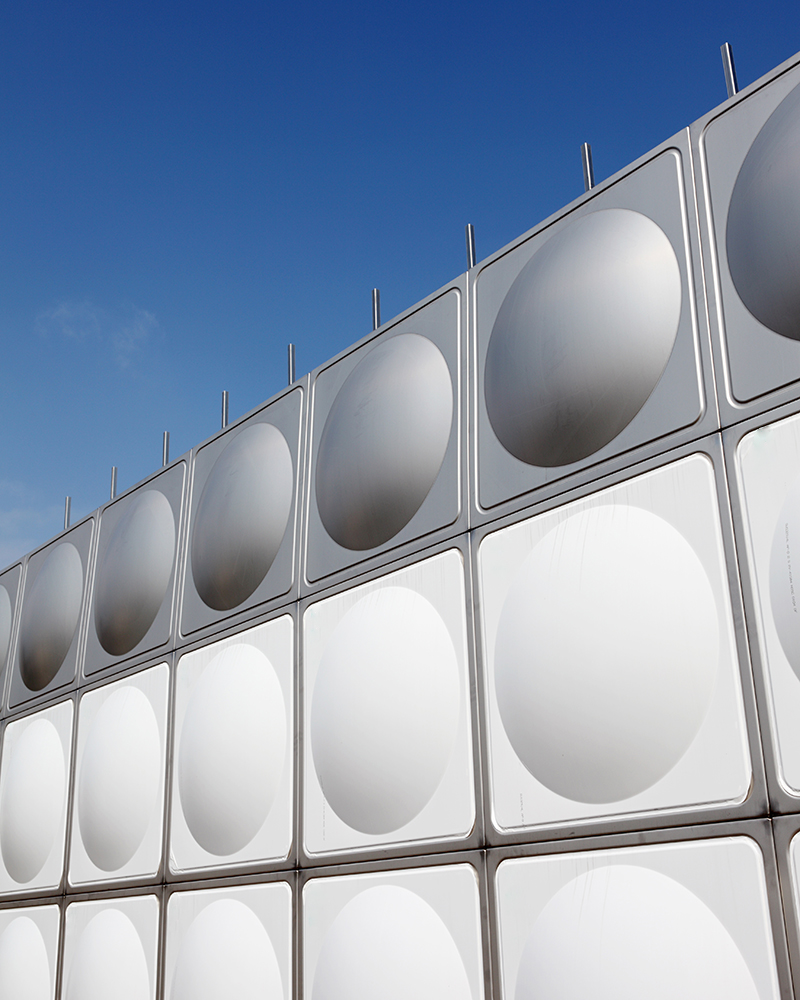

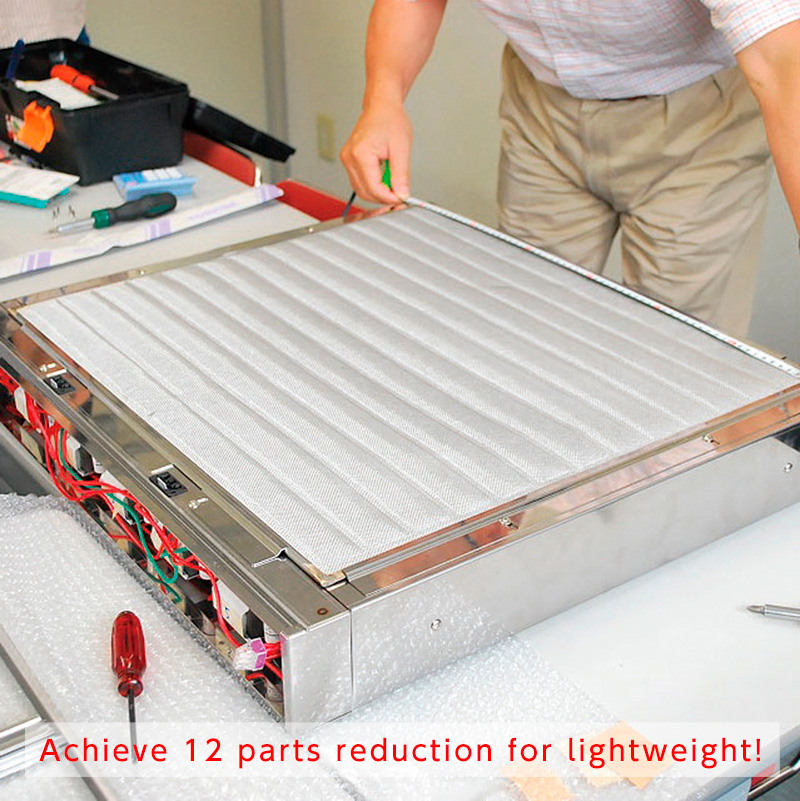

Case2:Example of photocatalyst deodorization equipment

Requests from customers

Equipment is very heavy. It would be a burden for workers. To make it installed more efficiently, we need to reduce its weights so we make it lighter. We are eliminating extra parts to keep cost down from the beginning.

Solution of Ohsato

・By reviewing parts we eliminate 12 unnecessary parts.

・23% lighter than the previous model.

・Energy consumption reduced by 15%.

Verification

・The product weight has been reduced easier handling.

・The products have been using continuously. The reasons are by working more efficiently energy consumption has been cut by 15%.

・We have had zero customer complaints about this issue.

“VA (Value Analysis) / VE (Value Engineering)” is a method for improving the value of existing products and new products. In Ohsato, it is possible to carry out at each stage, from zero look VE at the marketing and product development stage, first look VE at the development design stage, and second look VE to reduce the cost of existing products.